High performance conveyor belts, profiles & types ( - 20°C to 90°C ) 2mm Green, White, Rough top, FDA, PU, PVC, PVC, Jogging Conveyors from 0.8 mm to 5 mm thick, width up to 3000 mm.

In almost any food production process, Nitta Polyurethane and PVC conveyor belts can be used. Needless to say that all Nitta food-grade belts meet the requirements of the FDA and the European Union. Some customers require their food-grade belts to be blue, so that non-food particles can be detected. Nitta can offer a complete range of blue Polyurethane and PVC belts for that purpose.

BAKERIES AND CONFECTIONERY INDUSTRY

Bread, pastry, biscuits, sweets, chocolate... You name it! Nitta belts convey them all, in any stage of the process. Transfer problems between conveyors? Our Polyurethane belts are flexible enough to pass the smallest knife edges.

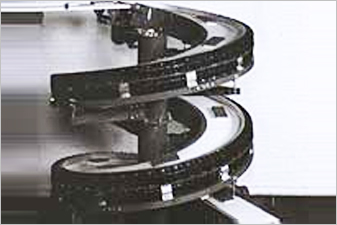

When transporting food products, often accessories are used on our belts such as carriers and corrugated sidewalls. For these processes, the choice of a Nitta belt is a natural one. Also for curved conveyors as shown above, we can serve you with a complete range.

MEAT AND POULTRY

| BELT TYPES | TOP COVER | THICKNESS (MM) | MIN. PULLY (MM) | TEMP. RANGE | WORKLOAD AT 1% ELONGATION | |

|---|---|---|---|---|---|---|

| MIN. °C | MAX. °C | |||||

| 1 LRFP 02 / W2 |M M | PU | 0, 7 | 6 | - 20 | + 80 | 4 N / mm |

| 1 RF 709 V | FELT | 3, 1 | 30 | - 10 | + 90 | 5 N / mm |

| 2 CF | FABRIC | 1, 8 | 20 | - 10 | + 90 | 8 N / mm |

| 2 LRF | FABRIC | 1, 6 | 20 | - 10 | + 90 | 8 N / mm |

| 2 LRF 704 / 001 | PVC | 2, 0 | 25 | - 10 | + 90 | 8 N / mm |

| 2 LRF 3704 / 001 | PVC | 2, 0 | 25 | - 10 | + 90 | 8 N / mm |

| 2 LRFP 02 / W2 | M M 1.4 | PU | 1, 4 | 8 | - 10 | + 80 | 8 N / mm |

| 2 LRFP 02 / LB2 | M M 1.4 | PU | 1, 4 | 8 | - 10 | + 80 | 8 N / mm |

| 2 LRFP 02 / W2 | M M 1.4 | PU | 1, 4 | 12 | - 10 | + 80 | 8 N / mm |

| 2 RF 71 | PVC | 2, 4 | 40 | - 10 | + 90 | 10 N / mm |

| 2 RF 71 SQPR | PVC | 2, 8 | 40 | - 10 | + 90 | 10 N / mm |

| 2 R 3710 | PVC | 3, 6 | 60 | - 10 | + 90 | 10 N / mm |

| 2 N 71 | PVC | 3, 2 | 50 | - 10 | + 90 | 12 N / mm |

| 3 N 71 | PVC | 4, 5 | 100 | - 10 | + 90 | 18 N / mm |

Nitta conveyor belts in PVC and Polyurethane are suitable for many processes: accumulation, inclined or declined transport, sideward loading/unloading. But do not think that a conveyor belt can only run straight ahead. Nitta has special belts for curved and spiral conveyors.

BUSINESS SERVICES

Whether it concerns luggage handling in airports, mail sorting in post offices, or scanning/sorting in a distribution centre, we have the range of belts that you need. Special whisper fabric is available for applications with slider bed support in areas where a low noise level is required. Flame retardant belts? We have a range of products that meets this demand.

MATERIALS HANDLING

| BELT TYPES | TOP COVER | THICKNESS (MM) | MIN. PULLY (MM) | TEMP. RANGE | WORKLOAD AT 1% ELONGATION | |

|---|---|---|---|---|---|---|

| MIN. °C | MAX. °C | |||||

| 1 LRAF 901 / 901 | FABRIC | 1, 6 | 30 | - 10 | + 90 | 9 N / mm |

| 2 LRAFP 02 / G2 | M M 1.4 | PU | 1, 4 | 8 | - 10 | + 80 | 8 N / mm |

| 2 LRAWF 91 | PVC | 2, 5 | 50 | - 10 | + 80 | 9 N / mm |

| 2 LRAWF 912 RB | PVC | 3, 2 | 40 | - 10 | + 80 | 9 N / mm |

| 2 LRAWF 1310 GP | PVC | 2, 8 | 40 | - 10 | + 80 | 9 N / mm |

| 2 LRF 2704 | PVC | 2, 0 | 25 | - 10 | + 90 | 8 N / mm |

| 2 LRF 272 RT 55° | PVC | 6, 0 | 50 | - 10 | + 80 | 8 N / mm |

| 2 LRF 904 M | PVC | 2, 0 | 25 | - 10 | + 80 | 8 N / mm |

| 2 LRAWF 916 WT | PVC | 4, 2 | 50 | - 10 | + 80 | 9 N / mm |

| 2 HRF 2712 | PVC | 2, 8 | 50 | - 10 | + 90 | 12 N / mm |

| 2 NF 906 AS - |M | PVC | 2, 3 | 50 | - 10 | + 90 | 12 N / mm |

| 2 XRFP 02 / PG2 |M M 1.9 | PU | 1, 9 | 20 | - 10 | + 80 | 9 N / mm |

| 2 N 71 | PVC | 3, 2 | 50 | - 10 | + 90 | 12 N / mm |

| 3 LRF 271 | PVC | 3, 6 | 100 | - 10 | + 80 | 12 N / mm |

| 3 LRWAF 901 | FABRIC | 3, 0 | 100 | - 10 | + 80 | 12 N / mm |

DATA ARE VALID AT 15°C & SUBJECT TO TOLARANCES. DUE TO CONSTANT DEVELOPMENTS WE RESERVE THE RIGHT TOMAKE CHANGES WITHOUT PRIOR NOTICE.